Name: BWG20 Galvanized Iron Wire

Material: Low carbon steel Q195

Specifications: 8#-22#

Name: BWG20 Galvanized Iron Wire

Name: BWG20 Galvanized Iron Wire

Material: Low carbon steel Q195

Specifications: 8#-22#

Wire Gauge: 0.7mm-4.0mm

Tensile Strength: 340-500/mm²

Zinc Coating: 20-240g/m²

Packing :

1. Inside with plastic film, outside weaving bag.

2. Inside with plastic film, outside hessian cloth

3. as customer's request

| wire gauge size | SWG(mm) | BWG(mm) | metric(mm) |

| 8 | 4.06 | 4.19 | 4.00 |

| 9 | 3.66 | 3.76 | _ |

| 10 | 3.25 | 3.4 | 3.50 |

| 11 | 2.95 | 3.05 | 3.00 |

| 12 | 2.64 | 2.77 | 2.80 |

| 13 | 2.34 | 2.41 | 2.50 |

| 14 | 2.03 | 2.11 | - |

| 15 | 1.83 | 1.83 | 1.80 |

| 16 | 1.63 | 1.65 | 1.65 |

| 17 | 1.42 | 1.47 | 1.40 |

| 18 | 1.22 | 1.25 | 1.20 |

| 19 | 1.02 | 1.07 | 1.00 |

| 20 | 0.91 | 0.89 | 0.90 |

| 21 | 0.81 | 0.813 | 0.80 |

| 22 | 0.71 | 0.711 | 0.70 |

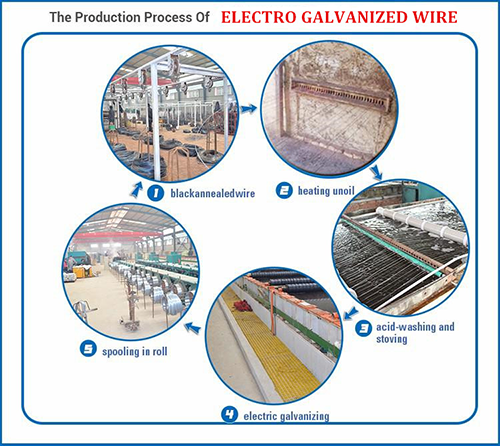

Electeo Galvanized Wire:

Black annealed wire → Heating unoil → Acid-washing and stoving → Electric galvanizing → Spooling in roll

Galvanized wire is really supernatural

The galvanized iron wire equipment is simply galvanized by wire. The wire we usually use is often visible because iron is very susceptible to corrosion and rust. Therefore, a layer of other non-rusting metal is plated on the outer layer to achieve resistance. Corrosion and anti-rust effects, such effect zinc can do more. Therefore, many customers often ask the hardware factory to produce galvanized iron wire, which requires the use of galvanized iron wire equipment.

The galvanized iron wire manufacturer has good anti-corrosion and anti-rust ability, so it can be prevented from being used on some outdoor fences or fences, especially in handicrafts. The handicrafts use galvanized iron wire, and the surface is not easy to rust. And oxidation. Nowadays, many hardware manufacturers produce iron wire, and the wire is very easy to rust. If it needs to be used outdoors or in a humid place, customers usually require galvanized iron wire equipment to apply a layer of zinc to the wire. The thickness can be determined according to user requirements. . Galvanized wire

Galvanized iron wire is available in both hot-dip galvanized and cold-galvanized. What are the differences between the two galvanized wires? Galvanized wire manufacturers introduce you. Zinc plating is immersed in hot melted zinc solution. The production speed is fast and the coating is thick but uneven. The market allows a minimum thickness of 45 microns and a maximum of 300 microns or more. The color is darker, consumes more zinc metal, forms an infiltrated layer with the base metal, and has good corrosion resistance. The hot-dip galvanizing can be maintained for several decades in an outdoor environment.

Hot-dip galvanized iron wire is made of high-quality carbon structural steel, which is processed by drawing and hot-dip galvanizing. Widely used in the manufacture of wire mesh, highway barriers and construction projects. It has the characteristics of thick coating, strong corrosion resistance and firm coating. According to the special needs of users, we can provide various specifications of galvanized wire according to industry standards.

It is a process in which the surface of the steel material is coated with a layer of metallic zinc to isolate the contact between the steel material and the air, including moisture, so as to avoid rust as much as possible. Zinc plating can also be divided into hot and cold plating. Hot-dip galvanized iron wire means that a layer of metal-zinc wire is plated on the outer surface of the wire by hot-plating.

Related Product Keywords:galvanized Iron Wire,electro Galvanized Wire.